Research for the sustainable use of resources

Resources form the basis for the economy, prosperity, security and innovation. This makes it all the more important to use them responsibly and sustainably. At TU Bergakademie Freiberg, technologies and solutions are developed to overcome key societal challenges in relation to the sustainable use of resources. Its profile combines the interlinked profile fields of GEO, MATERIAL, ENERGY and ENVIRONMENT in research and teaching and is consistently geared towards the requirements of the future.

Humanitarian responsibility, environmental and climate protection, efficient use of scarce raw materials and sustainable provision of energy are key motivators of our research. Many of the innovations resulting from our research contribute worldwide to the goal of closing the energy and material cycles.

Research areas of the faculties

Interdisciplinary centres (selection):

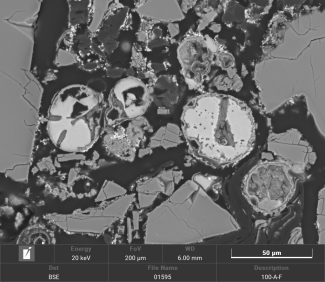

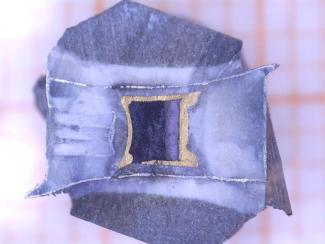

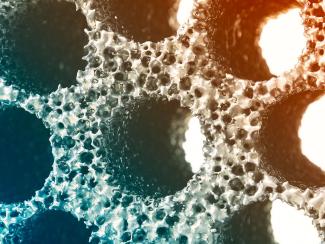

DFG Collaborative Research Centre 920 - Multifunctional filters for molten metal filtration

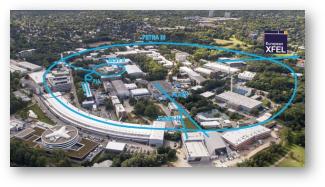

Excellent research infrastructures

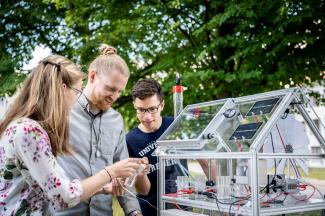

A particular strength of TU Bergakademie Freiberg is its excellent, in some cases unique, equipment and research infrastructure, which enables end-to-end technology developments based on basic research, modelling and simulation through to technology development on an industrial pilot scale.

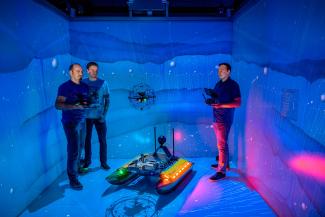

In addition to well-equipped laboratories and pilot plants in the fields of chemistry, physics, environmental and geosciences, geotechnics, metallurgy, glass and ceramics, process engineering, additive manufacturing, materials technology, robotics, foundry and forming technology, semiconductor and sensor technology as well as heat and energy technology, several central infrastructure facilities are available to researchers.

Facilities and equipment

Central infrastructure facilities:

- Behavioural Research Lab and Virtual Reality Lab

- HPC Cluster

- Central Clean Room Laboratory

- Scientific Diving Centre

- Geoscientific Collections

- Research and Teaching Mine

Partnerships, networks, alliances

The TU Bergakademie Freiberg is one of the top international addresses in the field of research into resource technologies and has been shaping developments in this field worldwide since its foundation. A large number of research institutions in the field of resource research can trace their origins directly back to TU Bergakademie Freiberg or scientists trained here. The network that has grown and the number of partnerships are correspondingly large. In addition to numerous national and international university, research and industry partnerships, TU Bergakademie Freiberg is actively involved in networks such as the European University Alliance EURECA-PRO - The European University on Responsible Consumption and Production and the German Resource Research Institute (GERRI). She was also the driving force behind the founding and development of the world's largest innovation network for resource technologies, EIT RawMaterials, with more than 120 partners from education, research and industry.

Numerous scientific institutions and research-related organisations and companies are located in Freiberg and the surrounding region. Partners at the site include the Helmholtz Institute Freiberg for Resource Technologies HIF, the Fraunhofer Technology Centre for High Performance Materials, the Fraunhofer Outstation for Carbon Cycle Technologies, the DBI - Gastechnologisches Institut gGmbH, the FILK Freiberg Institute, the Landesamt für Landwirtschaft, Umwelt und Geologie, the Sächsische Oberbergamt and several other affiliated institutes and industrial research organisations.

Saxon initiatives in which TU Bergakademie Freiberg is actively involved include Energy Saxony, Leichtbau-Allianz Sachsen, Sächsische Wasserstoff-Union, rECOmine, GlasCampus Torgau, Geocompetence Centre Freiberg, Freiberger Interessengemeinschaft der Recycling- und Entsorgungsunternehmen and Circular Saxony.

Several foundations are important sponsors of science and research. The Dr Erich Krüger Foundation, one of the largest university foundations in Germany, should be emphasised here, with the help of which projects worth well over 1 million euros can be implemented each year.

Research at the TU Bergakademie Freiberg

The university offers excellent working and environmental conditions for national and international researchers as well as the next generation of scientists. Collaboration within the university is characterised by short distances and direct communication between the academic departments, administration and university management in a collegial, innovation-friendly and supportive atmosphere. This enables individual and flexible solutions as well as the rapid and pragmatic realisation of ideas. Modern and generously equipped laboratories and pilot plants, access to an excellent infrastructure and access to renowned partner institutions worldwide enable the realisation of ambitious scientific projects and create a motivating environment.

Promoters, postdocs and visiting researchers are supported by a comprehensive range of support and services and encouraged in the implementation of their projects as well as in their individual qualification and personal development. In addition to peer networks, mentoring and coaching programmes, the Graduate and Research Academy GraFA and the International University Centre "Alexander von Humboldt" IUZ offer a wide range of further education and service programmes.

Freiberg offers a pleasant and family-friendly living environment for scientists, with attractive housing, leisure and cultural facilities, modern and lovingly equipped daycare centres and schools as well as medical care facilities.

Responsible research - ethical and quality standards

Our research is at the service of society. With our work and its results, we contribute to creating and maintaining good humanitarian and natural living conditions and to solving the major social challenges of resource, environmental and climate protection. We promote sustainable development in line with the United Nations Sustainable Development Goals (SDGs) as well as innovation-friendly, cosmopolitan, peaceful and tolerant coexistence.

The TU Bergakademie Freiberg is committed to the principles of good scientific practice and the requirements of the DFG Code of Conduct "Guidelines for Safeguarding Good Scientific Practice" and implements these in a binding manner for all researchers and students. Good scientific practice concerns scientific work and documentation, interaction and communication with students and staff and the publication of results. The corresponding regulations provide support and guidance. It also regulates how to deal with cases of conflict.

The TU Bergakademie Freiberg grants scientists a high degree of freedom. It encourages courage, creativity, entrepreneurship and a spirit of discovery. It strives for a culture of facilitation and support, curiosity and respectful interaction. This includes openness to new and unconventional approaches and methods. Scientists are treated with equal respect, included in the community and individually supported, regardless of gender, ethnic and cultural origin, religion, world view, individual limitations or orientations.

The TU Bergakademie Freiberg is committed to Open Science and supports the disclosure and dissemination of knowledge and research results for the benefit of humanity and the realisation of the goals of sustainable development. It is a signatory to the Berlin Declaration on Open Access to Knowledge in the Sciences and Humanities and provides its scientists with the necessary means to publish research results and data openly accessible. With the publication platform Qucosa and the research data repository OpARA, the university has its own repositories. In addition, TU Bergakademie Freiberg is part of the DEAL consortium and offers support for fee-based open access publications with an open access fund.

The university promotes science communication and the transfer of knowledge and technology to industry and society with various formats of its own, for example as part of the 4transfer project.

The TU Bergakademie Freiberg creates the necessary conditions for the professional and responsible handling, long-term preservation and accessibility of research data. We are a member of the National Research Data Infrastructure e.V. (NFDI) and our scientists are actively involved in the relevant specialist groups. We are also involved in the Saxon network SaxFDM (Research Data Management Saxony), which provides advice and support to Saxon researchers.

Vice-Rector Research, International Affairs and Transfer

Prof. Dr.-Ing. Tobias Fieback

University Main Building

Akademiestr. 6, 1st floor, room 1.04

prorektor-forschung [at] zuv [dot] tu-freiberg [dot] de (prorektor-forschung[at]zuv[dot]tu-freiberg[dot]de)

+49 3731 39-2552